A Day in the life of a Drayman

If you google “Definition of a Drayman,” the first thing that pops up is “a person who delivers beer for a brewery.” In a world of international shipping, many may find this comical. Comical notes aside, Wikipedia does explain the essence of a drayman. It reads that a “drayman was historically the driver of a dray, a low, flat-bed wagon without sides, pulled generally by horses or mules that were used for transport of all kinds of goods.”

Scarbrough has an array of close partners at each port when it comes to drayage companies and capabilities. Our accumulated volume and our close relationship with each partner allow us to pass on competitive rates and make our clients’ jobs easier by fully completing the last leg or beginning leg of an international move.

In a world of information, I thought I would make it easier for our clients to understand what exactly a drayage company did. In most instances, drayage companies only work direct with freight forwarders, because the freight forwarder will represent each client, knows the intermodal and international shipping language, has the relationship, rates in place, and most importantly provides the customer service clients require at the beginning or end of a shipment.

I went out and asked a couple of Scarbrough’s close drayage partners the following questions:

What is a dray service?

A dray is the truck transportation from one hub to the other within the intermodal chain. A dray service includes moving loaded and empty containers and chassis between rails, empty depots, shippers and receivers.

Who has the relationship with the dray service?

A freight forwarder or U.S. Customs broker predominantly has the relationship with drayage companies.

What types of requirements are involved with drayage?

Drayage requirements include compliance with DOT regulations and with organization regulating intermodal drayage such as UIIA. In fact, the drayage company must be a member of the UIIA and have knowledge of the local rail yard. The drayman must know the empty depot procedures which vary widely by rail/empty depot. Unfortunately there is no manual for this. It is just a learn-as-you-go process.

Do dray service providers also include chassis?

This depends on the drayage company and the port. Our Chicago drayage partners typically include chassis on all shipments. A chassis will also be included at times, when specialized equipment is needed, such as tri-axle chassis for movement of otherwise overweight 20′ units. Tri-axle chassis is more expensive than normal chassis. Typically, chassis is paid for per day and can range from $25-35 per day for a regular chassis. In some cases, chassis rates are included in the drayage move and in some cases are charged separately.

Why is a chassis required?

In short, to transport the container over the road. The loaded and empty units for international transit do not come with any sort of wheels. The containers are stacked on top of each other to maximize space on vessels and trains. The chassis allows the unit to be mounted and then transported to the shipper and receiver.

What does a typical day look like for a drayman?

Let’s start with very early mornings. Bet you didn’t realize that draymen will wake up in the middle of the night to allow pick up time from the rail yard and drive to a warehouse for an early morning appointment at the dock that you set. Many times, the day begins by utilizing all the various railroad search capabilities to see what has become available and determining which loads need to go at what time. Then the process begins of determining which loads will be most difficult to get out of said railyard, which varies by terminal. The drayage company will schedule appointments with receivers and shippers that require this. Sending notification to drivers of what loads they will be doing and where to secure chassis, containers and whatever else may be needed to complete the load. During all of this, the drayage company will stay in contact with the driver, receiver and shipper, and freight forwarder/broker in regards to timeliness and so forth, or any issues that arise.

What is a chassis split? When is it required?

A chassis split is when a container returns or picks up at one location, but that location does not have any chassis on the premises. Then the drayage company needs to source a chassis from another location to recover said container.

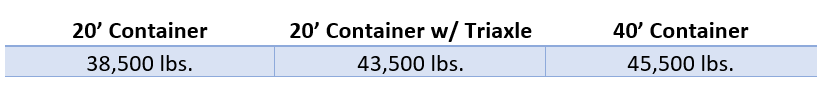

What are the legal road limits for 20’, 40’, etc.? Does this weight include the chassis weight?

The above is cargo weight only. This does not include the container tare or chassis tare weight. The weight limit for all is 80,000 lbs maximum, which includes truck, chassis, container and cargo.

What is the difference between a live unload and a drop & pick? What is the typical radius for a drop and pick?

Live unload: when the driver waits at the dock while unloading.

Drop and pick: when the driver leaves the container at the warehouse and picks it up at a later date.

A typical radius is about 75 miles, however some drayage companies are willing to travel much longer miles, of course at a cost. In fact, with the recently mandated Electronic Logging Device regulation, it is much harder to find a drayage company that will travel the long miles outside of their typical radius. Many of the drayage companies are charging a $400 flat fee or up to $500 simply to pay for the driver to sleep since long haulage moves are turning into overnight moves. To read more about the ELD Mandate and how it effects drivers and draymen, click here.

How often does FSC fluctuate? What source do you use to check market fuel prices?

Most drayage companies check on fuel surcharge rates weekly. Some drayage companies only change their FSC when there is a $.2 per gallon change. One can find more information on FSC rates from the U.S. Department of Energy.

What is a tri-axle?

In short, a tri-axle is a chassis with 3 axles in rear section. It is a chassis that has 3 axles in the rear of the unit to more evenly distribute the weight and help to spread the weight out to a legal allowable axle limit. It is required if the container is overweight.

What is a pre-pull? When is this advantageous?

A pre-pull is necessary when rail free time is about to expire. A freight forwarder or drayman may choose to pre-pull a client’s container to avoid higher rail storage charges when they cannot find driver capacity to actually deliver the freight or an appointment is required, for example. The client will still have to pay storage charges at the trucker’s own yard, but they will be a fraction of the cost of the railyard storage fees. Again, it is most advantageous when trying to avoid rail storage charges or to meet early appointment times.

What is a street turn?

Simply put, a street turn is utilizing an empty container from import delivery into an export load almost immediately. The import container is not returned to the depot before it is on its way for an export load. The abilities to do so are regulated by the steamship lines themselves as they determine if they will allow a street turn.

Conclusion

Thank you to Luigi with r2R Intermodal and Dave with CR Express for your answers and partnership! One last question and comment from our close friends:

What are your thoughts about Google’s Definition of a drayman?

“Makes me laugh, that is obviously an antiquated definition. And most certainly does not do justice to the people out there that do this for a living. I understand its origins, but feel it most certainly can be updated.” Dave, CR Express

Want to really see a day in the life of a drayman? Check out this video our friend, Luigi shared.

If you have any comments or questions, don’t hesitate to contact our team at info@scarbrough-intl.com. Thank you to our many drayage partners!