5 Emerging Technologies that are changing the Future of Logistics

Every industry is going through a transformational phase of automation and digitization. The logistics industry is no different and is confronting similar circumstances. A technological shift in the form of introduction of automotive technologies can be observed in the industry.

Automotive machines operated on artificial intelligence algorithms exhibit great potential in boosting the growth of the logistics industry. The real question is what the future of the logistics industry will look like?

1. Possibility of Autonomous Fleets

Self-driving cars or autonomous fleets is not an alien concept anymore. The project is in test phase and is one of the most promising sector exhibiting great possibilities for development.

Amazon is the pioneer of introducing automated technology in the form of drones to conduct deliveries. The trend has gained a massive popularity and the idea is being continuously developed and refined to be more practical. The trend of automation is expected to extend to the shipping and cargo industry. Currently the technology is restricted to drones and small-distance deliveries. However, automated fleets are definitely a thing of the future.

The technological advancements in the form of automation will result in increased efficiency of the overall industry. Increased efficiency will eventually lead to increased competition that will stimulate a pursuit of excellence.

In addition to being time efficient, automated cargo ships will also be cost-efficient. Automation of the shipping and docking processes implies that manual labor currently employed in these sectors will be replaced. In addition to that, advancement in technology means that more companies will be able to carry out truck platooning successfully. This technique is a potential cost saver as it is estimated that truck platooning can reduce the costs up to 20%.

2. Integrating 3D printing in the logistics structure

The scope of 3D printing is vast and is expanding at an exponential rate. In 2014, 3D printing market experienced an average annual growth rate of 35.2% globally. Market analysts believe that if our economy is going to change the way we manufacture products then the process will also have a significant impact on how we supply or receive those products.

3D printing can have multiple positive impacts on the logistics industry. It can completely alter the warehousing system. Development in the 3D printing technology implies that manufacturers can then opt for the option of printing-on-demand. This will in turn eliminate (or at least significantly reduce) the need to carry inventory and ultimately reducing the transportation and warehousing costs.

In addition to that, with the help of 3D printing technology, complex things can be printed instead of carrying out the manufacturing process at the assembly lines in the factories. This will substantially reduce the need for high volume production. It will reduce the manufacturing time and the costs associated with hiring of the labor to carry out manual tasks

3. Embracing a data-driven and Internet of Things (IoT) culture

By embracing a data-driven culture and opting for solutions provided by IoT, companies can improve the in-transit visibility of the goods. Currently the deliveries are made through third-party logistics or 3PL.

Services provided by 3PL can range from anywhere between providing a specific facility or maintaining the entire supply-chain system. It is difficult to track the goods when they are in transit. IoT eliminates the physical restriction by using active or passive RFID tags. These tags provide continuous data about the goods they are attached to. Many companies have already employed the technology in their business models to improve the efficiency of their operations.

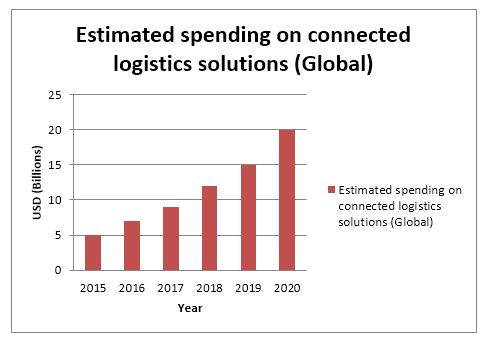

In addition to that, a major transformation that the logistics industry will observe will be in the form of connected fleet management. Connected fleet management solutions use GPS and various other tracking technologies to record the data about their large overseas fleets. It is estimated that by 2020 approximately 180 million commercial vehicles in US will employ the connected fleet management solutions.

Source: MarketandMarkets, 2015

4. Replacement of fuels to reduce the carbon-print

We have become more environmentally conscious than before. Every industry is making attempts to reduce their carbon-footprint by transferring to a sustainable and environmental friendly business model.

The cargo and shipping industry is following the suit. Some companies are trying to develop a technology by which ships can be operated via battery power so as to replace the use of gas and oil as fuels. Battery operated fleets will significantly reduce the air and water pollution currently caused by cargo ships.

5. Augmented Reality solutions

Augmented reality has revolutionized the way people interact with each other. The technology has a massive impact on every industry. Through augmented reality people can simulate the real life situations by computer-generated sensory inputs.

Augmented reality can significantly improve the efficiency of the operations performed in the logistics industry. With the help of AR technology, managers can get critical information about their fleet such as contents carried by the fleet, their weight and their destination. It can also help in identifying the potential damages and flaws in the ships or cargos beforehand. This in turn will reduce the overall operational costs of the company handling the logistics as well as improve their service.